Introduction

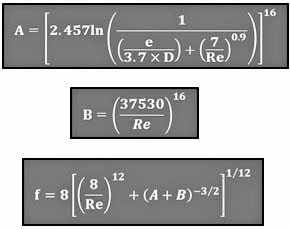

After a long time, I am returning to a subject that has bothered me many times in the past: friction factor. This time, however, I tried to switch my typical tools, so instead of an Excel/VBA solution, you will get a free online tool. The tool calculates the pipe friction factor based on Churchill’s equation. If you have read any of my previous posts, you will probably remember that Churchill’s equation is valid for the entire Reynolds range (e.g. any flow type). The equation involves the calculation of two intermediate values that are used in the final equation.

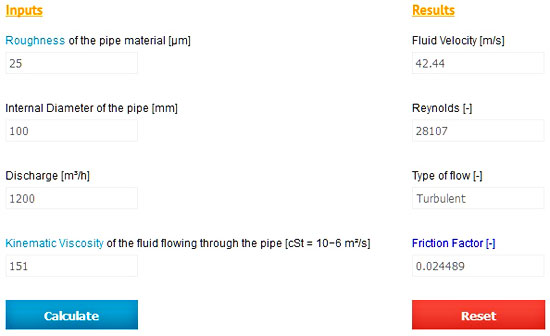

Pipe friction factor calculator

Inputs

The roughness of the pipe material [μm]

Internal Diameter of the (circular) pipe [mm]

Discharge [m³/h]

Kinematic Viscosity of the fluid flowing through the pipe [cSt = 10−6 m²/s]

Results

Fluid Velocity [m/s]

Reynolds [-]

Type of flow [-]

Friction Factor [-]

Table 1: Suggested roughness values for several pipe materials.

| Pipe Material | Roughness (μm) |

|---|---|

| Aluminum | 1.5 |

| Asbestos cement | 25 |

| Cast iron (asphalted) | 122 |

| Cast iron (uncoated) | 254 |

| Concrete (steel forms, with smooth joints) | 180 |

| Drawn brass | 1.5 |

| Drawn copper | 1.5 |

| Drawn tubing – glass, brass, plastic | 1.5 |

| Fiberglass | 5 |

| Fiberglass with epoxy | 3 |

| Galvanized iron | 152 |

| Polyethylene | 3 |

| PVC | 1.5 |

| Seamless commercial steel (galvanized) | 150 |

| Seamless commercial steel (light rust) | 250 |

| Seamless commercial steel (new) | 25 |

| Stainless steel | 45 |

| Welded steel | 600 |

| Wood stave | 600 |

| Wrought iron | 45 |

Table 2: Suggested kinematic viscosity values for various liquids.

| Liquid | Temperature (C) | Kinematic Viscosity (cSt) |

|---|---|---|

| Acetaldehyde CH3CHO | 16.1 | 0.305 |

| 20 | 0.295 | |

| Acetic acid – vinegar – 10% CH3COOH | 15 | 1.35 |

| Acetic acid – 50% | 15 | 2.27 |

| Acetic acid – 80% | 15 | 2.85 |

| Acetic acid – concentrated glacial | 15 | 1.34 |

| Acetic acid anhydride (CH3COO)2O | 15 | 0.88 |

| Acetone CH3COCH3 | 20 | 0.41 |

| Alcohol – allyl | 20 | 1.6 |

| Alcohol – butyl-n | 20 | 3.64 |

| Alcohol – ethyl (grain) C2H5OH | 20 | 1.52 |

| 37.8 | 1.2 | |

| Alcohol – methyl (wood) CH3OH | 15 | 0.74 |

| 0 | 1.04 | |

| Alcohol – propyl | 20 | 2.8 |

| 50 | 1.4 | |

| Aluminum sulfate – 36% solution | 20 | 1.41 |

| Ammonia | -17.8 | 0.3 |

| Aniline | 20 | 4.37 |

| 10 | 6.4 | |

| Asphalt RC-0, MC-0, SC-0 | 25 | 159-324 |

| 37.8 | 60-108 | |

| Automatic crankcase oil SAE 10W | -17.8 | 1295-max |

| Automatic crankcase oil SAE 10W | -17.8 | 1295-2590 |

| Automatic crankcase oil SAE 20W | -17.8 | 2590-10350 |

| Automatic crankcase oil SAE 20 | 98.9 | 5.7-9.6 |

| Automatic crankcase oil SAE 30 | 98.9 | 9.6-12.9 |

| Automatic crankcase oil SAE 40 | 98.9 | 12.9-16.8 |

| Automatic crankcase oil SAE 50 | 98.9 | 16.8-22.7 |

| Automotive gear oil SAE 75W | 98.9 | 4.2 min |

| Automotive gear oil SAE 80W | 98.9 | 7.0 min |

| Automotive gear oil SAE 85W | 98.9 | 11.0 min |

| Automotive gear oil SAE 90W | 98.9 | 14-25 |

| Automotive gear oil SAE 140 | 98.9 | 25-43 |

| Automotive gear oil SAE150 | 98.9 | 43 – min |

| Beer | 20 | 1.8 |

| Benzene (Benzol) C6H6 | 0 | 1 |

| 20 | 0.74 | |

| Bone oil | 54.4 | 47.5 |

| 100 | 11.6 | |

| Bromine | 20 | 0.34 |

| Butane-n | -1.1 | 0.52 |

| 0.35 | ||

| Butyric acid n | 20 | 1.61 |

| Calcium chloride 5% | 18.3 | 1.156 |

| Calcium chloride 25% | 15.6 | 4 |

| Carbolic acid (phenol) | 18.3 | 11.83 |

| Carbon tetrachloride CCl4 | 20 | 0.612 |

| 37.8 | 0.53 | |

| Carbon disulfide CS2 | 0 | 0.33 |

| 20 | 0.298 | |

| Castor oil | 37.8 | 259-325 |

| 54.4 | 98-130 | |

| China wood oil | 20.6 | 308.5 |

| 37.8 | 125.5 | |

| Chloroform | 20 | 0.38 |

| 60 | 0.35 | |

| Coconut oil | 37.8 | 29.8-31.6 |

| 54.4 | 14.7-15.7 | |

| Cod oil (fish oil) | 37.8 | 32.1 |

| 54.4 | 19.4 | |

| Corn oil | 54.4 | 28.7 |

| 100 | 8.6 | |

| Corn starch solution, 22 Baumé | 21.1 | 32.1 |

| 37.8 | 27.5 | |

| Corn starch solution, 24 Baumé | 21.1 | 129.8 |

| 37.8 | 95.2 | |

| Corn starch solution, 25 Baumé | 21.1 | 303 |

| 37.8 | 173.2 | |

| Cottonseed oil | 37.8 | 37.9 |

| 54.4 | 20.6 | |

| Crude oil 48o API | 15.6 | 3.8 |

| 54.4 | 1.6 | |

| Crude oil 40o API | 15.6 | 9.7 |

| 54.4 | 3.5 | |

| Crude oil 35.6o API | 15.6 | 17.8 |

| 54.4 | 4.9 | |

| Crude oil 32.6o API | 15.6 | 23.2 |

| 54.4 | 7.1 | |

| Decane-n | 17.8 | 2.36 |

| 37.8 | 1.001 | |

| Diethyl glycol | 21.1 | 32 |

| Diethyl ether | 20 | 0.32 |

| Diesel fuel 2D | 37.8 | 2-Ιουν |

| 54.4 | 1.-3.97 | |

| Diesel fuel 3D | 37.8 | 6-11.75 |

| 54.4 | 3.97-6.78 | |

| Diesel fuel 4D | 37.8 | 29.8 max |

| 54.4 | 13.1 max | |

| Diesel fuel 5D | 50 | 86.6 max |

| 71.1 | 35.2 max | |

| Ethyl acetate CH3COOC2H3 | 15 | 0.4 |

| 20 | 0.49 | |

| Ethyl bromide C2H5Br | 20 | 0.27 |

| Ethylene bromide | 20 | 0.787 |

| Ethylene chloride | 20 | 0.668 |

| Ethylene glycol | 21.1 | 17.8 |

| Formic acid 10% | 20 | 1.04 |

| Formic acid 50% | 20 | 1.2 |

| Formic acid 80% | 20 | 1.4 |

| Formic acid concentrated | 20 | 1.48 |

| Trichlorofluoromethane, R-11 | 21.1 | 0.21 |

| Dichlorodifluoromethane, R-12 | 21.1 | 0.27 |

| FDichloro-fluoromethane, R-21 | 21.1 | 1.45 |

| Furfurol | 20 | 1.45 |

| Fuel oil 1 | 21.1 | 2.39-4.28 |

| 37.8 | -2.69 | |

| Fuel oil 2 | 21.1 | 3.0-7.4 |

| 37.8 | 2.11-4.28 | |

| Fuel oil 3 | 21.1 | 2.69-5.84 |

| 37.8 | 2.06-3.97 | |

| Fuel oil 5A | 21.1 | 7.4-26.4 |

| 37.8 | 4.91-13.7 | |

| Fuel oil 5B | 21.1 | 26.4- |

| 37.8 | 13.6-67.1 | |

| Fuel oil 6 | 50 | 97.4-660 |

| 71.1 | 37.5-172 | |

| Gas oils | 21.1 | 13.9 |

| 37.8 | 7.4 | |

| Gasoline a | 15.6 | 0.88 |

| 37.8 | 0.71 | |

| Gasoline b | 15.6 | 0.64 |

| 37.8 | ||

| Gasoline c | 15.6 | 0.46 |

| 37.8 | 0.4 | |

| Glycerine 100% | 20.3 | 648 |

| 37.8 | 176 | |

| Glycerine 50% water | 20 | 5.29 |

| Glycol | 52 | |

| Glucose | 37.8 | 7.7M-22M |

| 65.6 | 880-2420 | |

| Heptanes-n | -17.8 | 0.928 |

| 37.8 | 0.511 | |

| Hexane-n | -17.8 | 0.683 |

| 37.8 | 0.401 | |

| Honey | 37.8 | 73.6 |

| Hydrochloric acid | 1.9 | |

| Ink, printers | 37.8 | 550-2200 |

| 54.4 | 238-660 | |

| Insulating oil | 21.1 | 24.1 max |

| 37.8 | 11.75 max | |

| Kerosene | 20 | 2.71 |

| Jet Fuel | -34.4 | 7.9 |

| Lard | 37.8 | 62.1 |

| 54.4 | 34.3 | |

| Lard oil | 37.8 | 41-47.5 |

| 54.4 | 23.4-27.1 | |

| Linseed oil | 37.8 | 30.5 |

| 54.4 | 18.94 | |

| Mercury | 21.1 | 0.118 |

| 37.8 | 0.11 | |

| Methyl acetate | 20 | 0.44 |

| Methyl iodide | 20 | 0.213 |

| Menhaden oil | 37.8 | 29.8 |

| 54.4 | 18.2 | |

| Milk | 20 | 1.13 |

| Molasses A, first | 37.8 | 281-5070 |

| 54.4 | 151-1760 | |

| Molasses B, second | 37.8 | 1410-13200 |

| 54.4 | 660-3300 | |

| Molasses C, blackstrap | 37.8 | 2630-5500 |

| 54.4 | 1320-16500 | |

| Naphthalene | 80 | 0.9 |

| Neatstool oil | 37.8 | 49.7 |

| 54.4 | 27.5 | |

| Nitrobenzene | 20 | 1.67 |

| Nonane-n | -17.8 | 1.728 |

| 37.8 | 0.807 | |

| Octane-n | -17.8 | 1.266 |

| 37.8 | 0.645 | |

| Olive oil | 37.8 | 43.2 |

| 54.4 | 24.1 | |

| Palms oil | 37.8 | 47.8 |

| 54.4 | 26.4 | |

| Peanut oil | 37.8 | 42 |

| 54.4 | 23.4 | |

| Pentane-n | 17.8 | 0.508 |

| 26.7 | 0.342 | |

| Petrolatum | 54.4 | 20.5 |

| 71.1 | 15 | |

| Petroleum ether | 15.6 | 31(est) |

| Phenol, carbolic acid | 11.7 | |

| 20 | 1.13 | |

| Propylene glycol | 21.1 | 52 |

| Quenching oil | 100-120 | |

| (typical) | ||

| Rapeseed oil | 37.8 | 54.1 |

| 54.4 | 31 | |

| Rosin oil | 37.8 | 324.7 |

| 54.4 | 129.9 | |

| Rosin (wood) | 37.8 | 216-11M |

| 93.3 | 108-4400 | |

| Sesame seed oil | 37.8 | 39.6 |

| 54.4 | 23 | |

| Silicate of soda | 79 | |

| Sodium chloride 5% | 20 | 1.097 |

| Sodium chloride 25% | 15.6 | 2.4 |

| Sodium hydroxide (caustic soda) 20% | 18.3 | 4 |

| Sodium hydroxide (caustic soda) 30% | 18.3 | 10 |

| Sodium hydroxide (caustic soda) 40% | 18.3 | |

| Soya bean oil | 37.8 | 35.4 |

| 54.4 | 19.64 | |

| Sperm oil | 37.5 | 21-23 |

| 54.4 | 15.2 | |

| Sulphuric acid 100% | 20 | 14.56 |

| Sulphuric acid 95% | 20 | 14.5 |

| Sulphuric acid 60% | 20 | 4.4 |

| Sulphuric acid 20% | ||

| Tar, coke oven | 21.1 | 600-1760 |

| 37.8 | 141-308 | |

| Tar, gashouse | 21.1 | 3300-66M |

| 37.8 | 440-4400 | |

| Tar, pine | 37.8 | 559 |

| 55.6 | 108.2 | |

| Toluene | 20 | 0.68 |

| Triethylene glycol | 21.1 | 40 |

| Turpentine | 37.8 | 86.5-95.2 |

| 54.4 | 39.9-44.3 | |

| Varnish, spar | 20 | 313 |

| 37.8 | 143 | |

| Water, distilled | 20 | 1.0038 |

| Water, fresh | 15.6 | 1.13 |

| 54.4 | 0.55 | |

| Water, sea | 1.15 | |

| Whale oil | 37.8 | 35-39.6 |

| 54.4 | 19.9-23.4 | |

| Xylene-o | 20 | 0.93 |

Read also

Solutions Of Colebrook & White Equation

10 + 1 Ways To Find The Friction Factor In Pipes

Friction Factor Function

Pressure Losses In Piping Systems

Head And Pressure Losses In Pipes

Page last updated: 29/02/2020